SOVAL research team

March 2018

In the Book of Agriculture the gardener of the emir of Toledo, Ibn Bassal, classified ten classes of soil in 1085 AD. Each class with different life-sustaining capabilities according to the season of the year [1]. Felix Beck started the Soval research group at NYU Abu Dhabi to look into solutions for the melioration of leached soil in agricultural areas, and to follow Ibn Bassal's effort in achieving maximum outcome without destroying soil and plants.

Problem Statement: How to feed the world? Soil Degradation as a major reason of concern.

The world population grows, and in 2016, 108 million people were reported to be facing crisis level food insecurity or worse [2]. In other words there is an absolute shortage of the available, annually produced foodstuffs. Farmers turn to traditional fertilisers to temporarily address the problem. However, over-fertilisation results in many cases to eutrophication and often leads to agricultural mismanagement. Moreover, the use of fertilisers destabilises the pH value in the long term and valuable trace elements leave the soil [3].

Usual chemical fertilisers contain nutrients that exclusively benefit plants and do not replace the elements extracted from the soil by crops.

As a result, the soil degrades after a certain time, the efficiency of the added chemical fertiliser decreases and the necessary demand for fertiliser increases to achieve the same yields. Increased fertiliser consumption aggravates the situation even more and is therefore economically counterproductive.

Demands:

- Preventing arable soil from leaching,

- Increasing the value of the farm land,

- Respecting the environment by using an environmentally friendly product

Goal:

- Low-cost soil melioration for high agricultural productivity to reprocess leached agricultural land,

- This should be achieved by the increase in natural fertility and not by the increased use of conventional fertilisers.

Background research

Beginning in the 1880s, phosphor based fertiliser was produced as a byproduct of the Thomas Process (a process of steel production) – the so called Thomasmehl. However, due to the ever-rising costs of integrating Phosphorus into the process, this kind of fertiliser is no longer available (its production stopped in 1980). Nevertheless, the current technique for steel production still results in a nutrient rich byproduct called slag.

The issue is that slag does not contain enough Phosphorus to be an effective fertiliser. In search of alternative Phosphorus sources, due to dwindling natural availability, researchers have identified potential in Sewage sludge ashes [4].

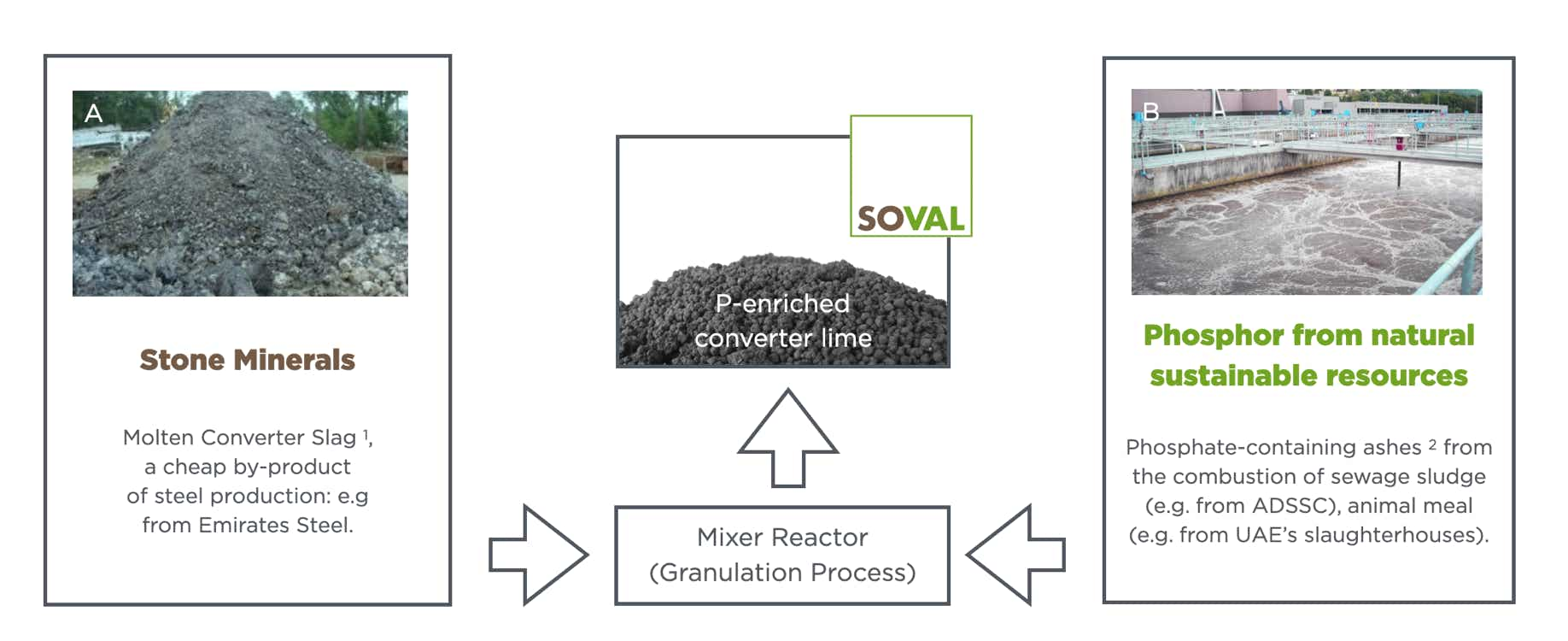

Steel mill slag (A) is mainly a residual product from the reduction of iron ore in the blast furnace and the limestone added during the oxidation process in the converter. Therefore, they have all the trace elements of the iron ore and the limestone in concentrated form, but in a natural ratio to one another. Because of the high thermal load in the converter, these elements are digested and are therefore available to plants. However, certain compounds, which are required in high doses, such as phosphorus, must be added.

As mentioned, research projects show that Phosphate-containing ashes (B) from the combustion of sewage sludge or animal meal are available sources of Phosphor in the UAE.

Two waste products: Converter Slag (a by-product of steel production generally used as cheap building material) and, for example, Phosphate-containing ashes from the combustion of sewage sludge can be used as basis as a fertiliser.

1,2 Research Paper by Arbeitsgemeinschaft Hüttenkalk e.V.:

Plant availability of phosphates from sewage sludge and animal meal ashes after digestion in liquid converter slag

The team has identified a solution for a high-quality fertiliser which can be produced from sustainable and low-cost resources.

The team found out that there was currently no follow-up project. So, the idea of developing a new product was born: SOVAL – Soil Value.

SOVAL is a highly beneficial calcium-silicium phosphate granulate produced out of waste products. It is a low-cost soil melioration agent that provides the nutrients needed to maintain high agricultural productivity.

SOVAL is a soil melioration agent in granulate form made from mineral raw materials suitable for field fruits and soils – especially, acidic soils.

It increases macronutrients within soils that have a diminishing earnings capacity.

SOVAL can be applied either mechanically or manually because contact is neither harmful to humans nor animals, posing no health risks.

Since the product is not water soluble, it can be used at any time of the year, and due to its granulate form it is not receptive to wind erosion.

The granulate stays where it belongs: at the roots of the crops.

SOVAL regulates soil moisture, prevents soil clogging, and controls the pH value. The phosphate contained therein is in readily absorbable form. Micronutrients include, among others, lime, silicon, magnesia, manganese, and iron in plant-available form and sufficient quantity to improve

the productive capacity of the soil.

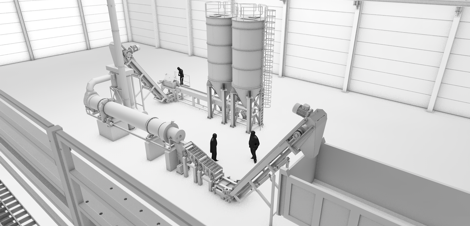

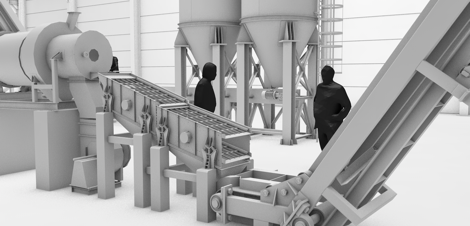

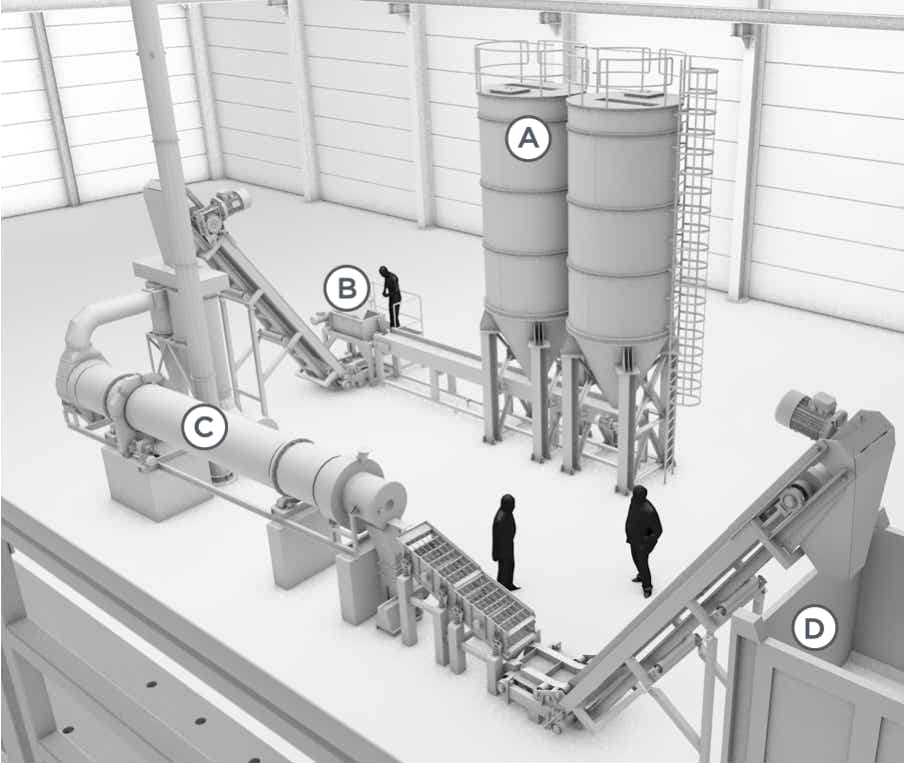

Development of a Mixer Reactor Plant

Based on the research a Mixer Reactor Plant was designed to create a follow-up product for the Thomas Mehl. The production process is relatively simple: The raw material (A) is comminuted, ground by means of a ball mill, screened - with additives introduced - and then fed to a mixer reactor (B). In a dry drum (C), the product is formed into granules, which are then either sown or stored in silos ready for transport (D).

The product treated in this way, if satisfactory with regard to grain size and chemical composition, is an excellent, mineral fertilizer and at the same time suitable for the melioration of degraded soils. It not only provides the plants with the necessary nutrients, such as phosphorus and lime, but also enriches the soil with the missing constituents and trace elements.

The team developed the concept for the Granulation Process and created the masterplan for an industrial plant.

Are you interested in a collaboration?

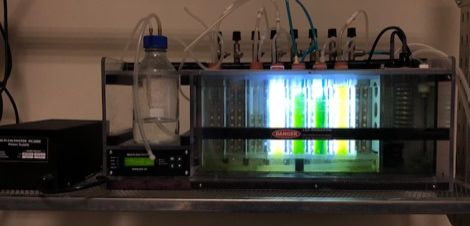

Felix Beck with his team members have done early field experiments with small amounts of SOVAL mixed from available ressources in the United Arab Emirates. Partners were the Abu Dhabi Waste Water Plant Al Wathba an Emirates Steel. The team has also developed a business model incl. financial plan, to produce and market the product, with the needed partners. Nevertheless the team did not receive sufficient funding to build a Mixer Reactor test plant. The project is on hold since then.

If you are interested in the project, please contact Felix Beck.

- 1001 Inventions, The Enduring Legacy of Muslim Civilisation, Salim T.S. Al-Hassani, 2012

- FAO study, Global Report on Food Crises 2017

- Data on Soil Degradation, World Resources Institute (International Soil Reference and Information Centre)

- Sewage sludge ash — A promising secondary phosphorus source for fertilizer production, Hannes Herzel, Germany, 2015